Kestabilan yang tinggi

Toleransi kecil dan kebarangkalian rendah produk yang rosak.

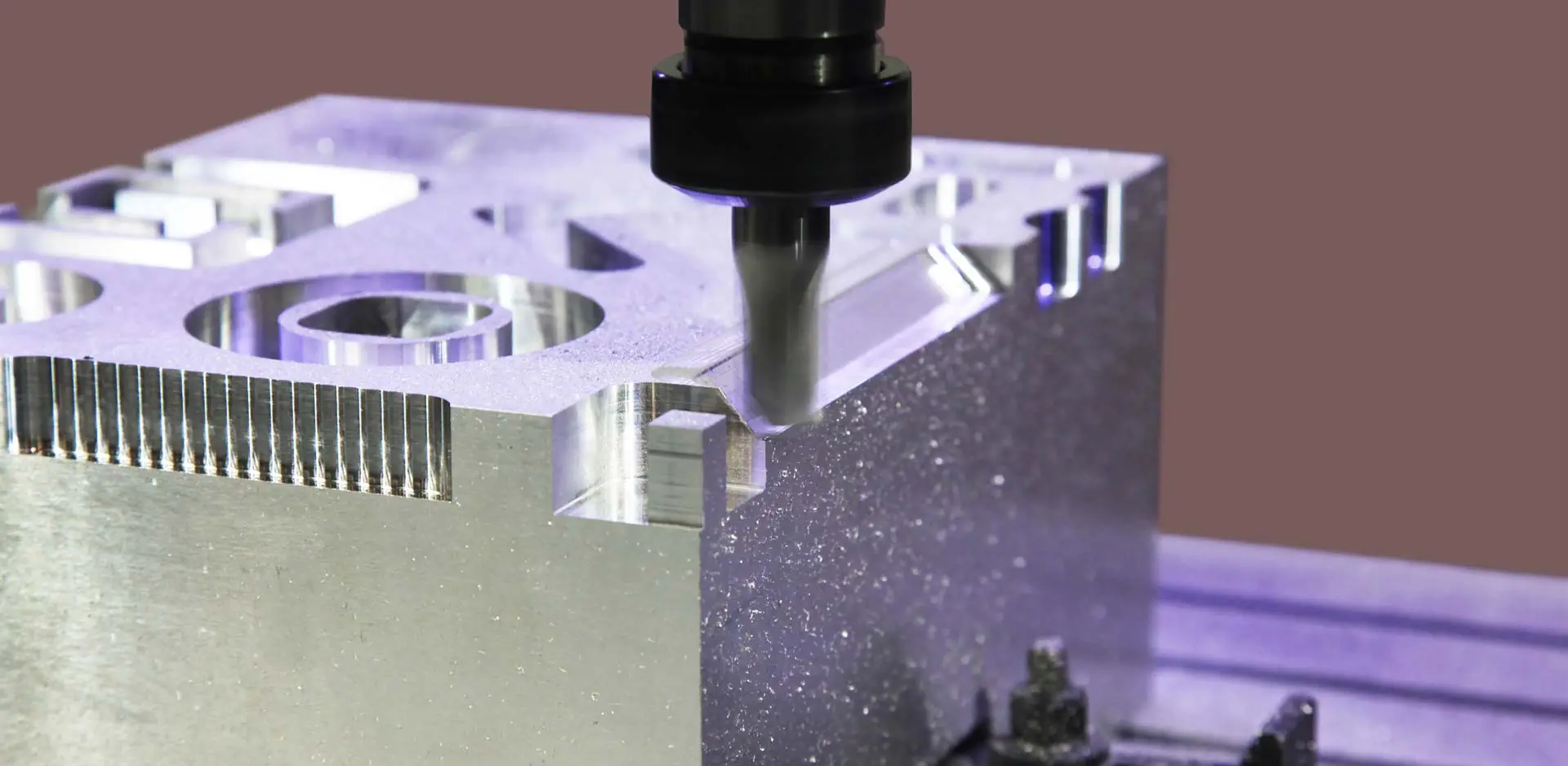

Ketepatan tinggi

Boleh menghasilkan bahagian aloi aluminium yang kompleks.

Kecekapan tinggi

Boleh menjimatkan kos buruh, dan dapat merealisasikan pengeluaran pelbagai dan besar-besaran.

Nama | Bahagian pemesinan CNC aluminium |

Jenis bahan | 5083, 5052, 6061, 7075, 1100, dll. |

Rawatan permukaan | Galvanization, Anodization, pembersihan ultrasonik, memohon minyak anti karat, Phosphating, poland, anneal, dan sebagainya. |

Jenis | Bahagian-bahagian alatan yang tidak standard kepersisan tinggi (perkhidmatan OEM) |

Warna | Hitam, perak, dll. |

Permohonan | Bahagian automotif ketepatan,Pemesinan ketepatan tinggi aeroangkasa,Bahagian ketepatan perubatan,Tenaga baru, Pemanasan elektrik,Komponen ketepatan untuk peralatan rumah tangga, Dan sebagainya. |

Sijil | IATF16949 2016;I SO9001 2015; ISO14001:2015;RoHS;REACH |

Pengeluar bahagian automotif ketepatan: Aloi aluminium digunakan secara meluas dalam pelbagai bahagian dalam industri automotif. Sebagai contoh, komponen enjin (seperti kepala silinder, crankshafts, rod penyambung), komponen casis (seperti sistem penggantungan, peranti stereng), dan struktur badan (seperti pintu, bumbung) semua boleh menggunakan bahagian pemesinan CNC aluminium.

Pemesinan cnc aeroangkasa: Oleh kerana kekuatan yang baik dan sifat ringan, aloi aluminium digunakan secara meluas dalam industri aeroangkasa. Bahagian pemesinan CNC aluminium digunakan dalam pembuatan komponen struktur pesawat (seperti sayap, fuselages), komponen enjin (seperti bilah turbin, pengambilan udara) dan peranti aeroangkasa.

Peralatan elektronik dan komunikasi: aluminium CNC machined parts memainkan peranan penting dalam peralatan elektronik dan komunikasi. Sebagai contoh, radiator untuk komputer dan pelayan, perumahan untuk peralatan elektronik, penyambung dan bingkai untuk peralatan komunikasi, dan lain-lain, semuanya boleh menjadi bahagian mesin CNC yang diperbuat daripada aloi aluminium.

Industri jentera: bahagian pemesinan CNC aluminium digunakan secara meluas dalam industri jentera. Mereka boleh digunakan untuk mengeluarkan pelbagai peralatan mekanikal dan komponen alat, termasuk bahagian alat mesin, komponen sistem hidraulik dan pneumatik, penghantaran, perumahan galas dan sokongan struktur, dan sebagainya.

Pemesinan ketepatan peranti perubatan: Berat ringan dan rintangan kakisan aloi aluminium menjadikannya ideal untuk digunakan dalam pembuatan peranti perubatan. Aluminium CNC machined parts digunakan dalam pembuatan peralatan perubatan dan instrumen untuk membuat bingkai katil, alat pembedahan, kurungan dan struktur sokongan, antara lain.

Tenaga dan tenaga boleh diperbaharui: bahagian pemesinan CNC aluminium mempunyai pelbagai aplikasi dalam sektor tenaga dan tenaga boleh diperbaharui. Sebagai contoh, ia digunakan dalam pembuatan bilah untuk turbin angin, kurungan dan struktur sokongan untuk pemasangan solar, dan banyak lagi.

Toleransi (terdedah): 0.001mm

Bahan: aluminium

Proses kerja: CNC Turning, pengilangan CNC, pemesinan CNC, pengisaran, Threading, mengetuk, membongkok, kimpalan, penggerudian, penempaan, pemotongan wayar EDM,

Selesai: Electroless nikel penyaduran, nikel/zink/Tin/Chrome/perak/emas/Teflon/penyaduran

Menggilap, jatuh, Passivation, rawatan haba, letupan pasir, bersalut zink, Anodized, filem kimia lain, dll.

Permohonan: kereta, NewEnergy, penerbangan, perubatan, pemanasan elektrik, termostat, peralatan rumah, Radar, barangan pengguna, dll.

Peralatan ujian: 3DCMM, mesin pemeriksaan automatik, penguji semburan garam, projektor 2D, VMS, mikroskop kamera industri, instrumen pemeriksaan optik CCD, penguji ketebalan salutan sinar-X, penguji lekatan, dan sebagainya.

Sijil: ISO9001:2015,ISO14001: 2015,ISO 13485: 2016, AS9100D, IATF16949: 2016

Format fail: CAD, PDF, SOLIDWORKS, STP, langkah, IGS, dll.

Tempat asal: Shenzhen/Huizhou, Guangdong, China

Tempoh pembayaran: T/T, L/C, Western Union, dll.

Masa penghantaran: 3 ~ 7 hari untuk sampel, 7 ~ 30 hari untuk pengeluaran besar-besaran

Terma perdagangan: EXW, FOB, CIF, CFR, DAP, DDP, DDU, FCA, dll.

Pembungkusan: pita dan reel, dulang membentuk vakum, kotak kadbod, dulang lepuh, Pallet, kes kayu, dll.

Cara penghantaran: ekspres (DHL, FedEx, UPS, TNT), melalui laut, melalui udara, dengan kereta api, atau keperluan anda.

Berikut adalah kelebihan perkhidmatan yang kami tawarkan untuk bahagian pemesinan CNC Aluminium adat:

Sokongan reka bentuk kejuruteraan:Pasukan kejuruteraan berpengalaman kami menyediakan sokongan reka bentuk profesional untuk mengoptimumkan reka bentuk produk, meningkatkan prestasi, dan mengurangkan kos untuk pelanggan kami.

Pengeluaran tersuai:Kita boleh menyesuaikan bahagian pemesinan CNC Aluminium mengikut keperluan pelanggan tertentu, termasuk dimensi, bentuk, bahan, rawatan permukaan, dan sebagainya, untuk memenuhi keperluan individu.

Kawalan kualiti yang ketat:Kami telah menubuhkan sistem pengurusan kualiti yang komprehensif yang meliputi semua peringkat dari perolehan bahan mentah untuk kawalan proses pengeluaran dan pemeriksaan produk akhir. Ini memastikan kualiti produk yang stabil dan boleh dipercayai.

Kapasiti pengeluaran fleksibel:Keupayaan pengeluaran fleksibel kami membolehkan kami dengan cepat menyesuaikan pengeluaran mengikut jumlah pesanan pelanggan, memastikan penghantaran tepat pada masanya dan memenuhi permintaan pelanggan.

Jadual penghantaran yang ketat:Kami mematuhi jadual penghantaran dengan ketat. Untuk item stok, pesanan segera dihantar apabila diterima, dengan pilihan untuk laut, tanah, atau pengangkutan udara. Untuk produk yang disesuaikan, proses reka bentuk bersepadu kami menjamin penghantaran cepat dalam masa 1-4 minggu.

Perkhidmatan selepas jualan yang komprehensif:Kami menyediakan perkhidmatan selepas jualan yang komprehensif, termasuk panduan penggunaan produk, sokongan teknikal, dan penyelenggaraan selepas jualan, untuk memastikan bahawa sebarang isu yang dihadapi oleh pelanggan semasa penggunaan produk dapat ditangani dengan segera.

Komited untuk kecemerlangan sebagai pembekal bahagian pemesinan CNC aluminium terkemuka, kami menyediakan pelanggan dengan bahagian pemesinan CNC Aluminium berkualiti tinggi, berprestasi tinggi, membantu mereka meningkatkan inovasi dan daya saing produk di pasaran.