Di syarikat kami, kami menggunakan proses yang sangat cekap untuk menghasilkan bahagian pemesinan CNC yang memenuhi keperluan khusus pelanggan kami. Berikut adalah gambaran keseluruhan proses yang kami ikuti:

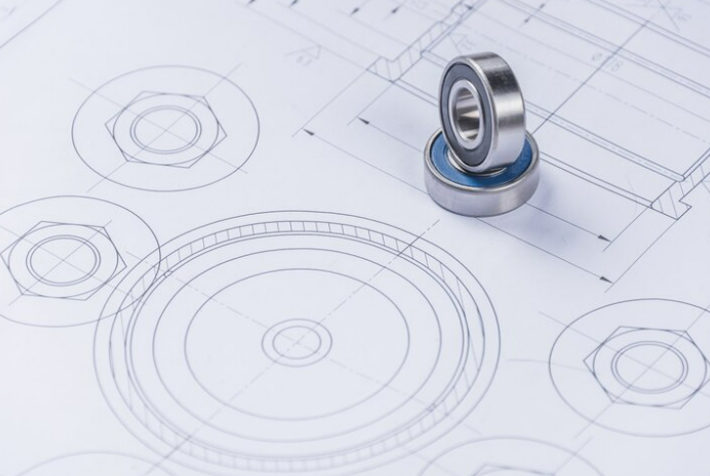

Reka bentuk dan pengaturcaraan: jurutera mahir kami bekerja dengan perisian terkini untuk mereka bentuk dan memprogram bahagian, memastikan ia memenuhi spesifikasi dan toleransi yang diperlukan.

Pemilihan bahan: kami berhati-hati memilih bahan yang sesuai untuk bahagian itu, dengan mengambil kira kekuatan, ketahanan, dan sifat-sifat lain.

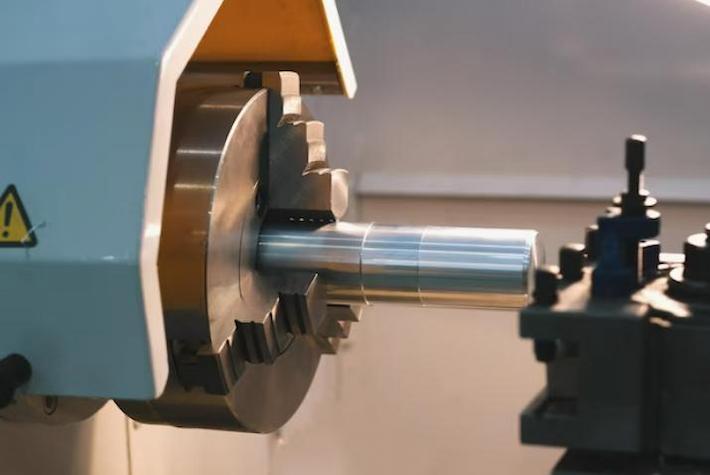

CNC Machining: kami menggunakan mesin kawalan komputer canggih untuk melaksanakan proses pemesinan CNC, yang melibatkan mengeluarkan bahan yang berlebihan dari bahan kerja untuk mencipta bentuk akhir bahagian.

Pemeriksaan kualiti: pasukan kami memeriksa bahagian-bahagian di setiap peringkat proses, menggunakan teknologi dan peralatan terkini untuk memastikan setiap bahagian memenuhi piawaian kualiti yang diperlukan.

Penamat: kami menawarkan pelbagai pilihan penamat, termasuk sandblasting, penggilap, anodizing, dan salutan, untuk meningkatkan penampilan dan fungsi bahagian-bahagian.

Pembungkusan dan penghantaran: kami berhati-hati membungkus bahagian-bahagian untuk memastikan ketibaan selamat mereka dan segera menyampaikannya kepada pelanggan kami.

Dengan komitmen kami terhadap kualiti, kecekapan, dan kepuasan pelanggan, kami telah membina reputasi sebagai pembekal yang dipercayai bahagian pemesinan CNC adat. Jika anda mempunyai projek yang memerlukan bahagian pemesinan CNC berkualiti tinggi, sila hubungi kami untuk membincangkan keperluan anda dan bagaimana kami dapat membantu.

Penerangan | Pengilangan CNC | CNC berpaling |

Bahan-bahan | Aluminium/Cu/keluli/tahan karat | Aluminium/Cu/keluli/tahan karat |

Saiz bahagian maksimum | 1000mm * 1000mm * 600mm | 1000mm * 600mm * 600mm |

Masa utama Standard | 4 hari bekerja | 4 hari bekerja |

Toleransi (± mm) | Pengilangan sahaja: sehingga ± 0.025mm Dengan memotong wayar atau EDM: sehingga 0.002mm | Sehingga ± 0.0025mm |

Jaminan kualiti | ISO 9001, ISO 45001:2018 Audit pembekal Projektor mengukur CMM dan 2D Laporan pemeriksaan Pemeriksaan fungsian Persampelan adat | ISO 9001, ISO 45001:2018 Audit pembekal Projektor mengukur CMM dan 2D Laporan pemeriksaan Pemeriksaan fungsian Persampelan adat |

Ketepatan dan ketepatan yang tinggi: dengan pemesinan CNC, bahagian boleh dihasilkan dengan toleransi yang sangat ketat dan ketepatan yang tinggi, memberikan tahap konsistensi yang sukar dicapai dengan proses pemesinan manual.

Pelbagai bahan: pemesinan CNC boleh digunakan dengan pelbagai bahan, termasuk logam, plastik, kayu, dan komposit.

Kos efektif untuk pengeluaran volum tinggi: pemesinan CNC sangat sesuai untuk pembuatan volum tinggi kerana ia membolehkan pengeluaran sejumlah besar bahagian pada kos yang lebih rendah setiap bahagian.

Peningkatan kecekapan: sifat automatik pemesinan CNC bermakna pengeluaran boleh dijalankan dengan lebih cekap, tanpa memerlukan campur tangan manual, mengakibatkan masa pengeluaran yang lebih cepat.

Fleksibiliti: pemesinan CNC boleh digunakan untuk menghasilkan komponen kompleks dengan bentuk rumit dan geometri, menjadikannya sesuai untuk pelbagai aplikasi.

Dalam bidang pembuatan ketepatan, kawalan berangka komputer (CNC) pemesinan berdiri sebagai marvel teknologi yang telah merevolusikan industri pengeluaran. Pemesinan CNC melibatkan penggunaan sistem berkomputer untuk mengawal alat dan proses mesin, yang membolehkan pengeluaran dan komponen yang rumit dan cekap. Pelbagai proses pemesinan CNC di bawah HHC mempunyai skop aplikasi yang berbeza dan ciri pemprosesan. Berikut menyediakan pengelasan dan pengenalan terperinci.

Salah satu jenis pemesinan CNC yang paling biasa, penggilingan menggunakan alat pemotong berputar untuk mengeluarkan bahan dari bahan kerja. Mesin penggilingan boleh bergerak sepanjang pelbagai paksi, mewujudkan pelbagai bentuk, slot, dan lubang. Dari komponen mudah ke prototaip kompleks, penggilingan adalah serba boleh dan digunakan secara meluas dalam industri seperti aeroangkasa, automotif, dan elektronik.

Dalam mengubah operasi, bahan kerja berputar sementara alat pemotong membentuknya ke dalam bentuk yang dikehendaki. Jenis pemesinan CNC ini sesuai untuk mewujudkan komponen silinder seperti aci, bolt, dan gelendong. Precision turning adalah asas proses pembuatan, memberikan kecekapan dan ketepatan untuk pelbagai aplikasi.

Seperti namanya, mesin CNC penggerudian direka untuk membuat lubang dalam bahan kerja. Mesin ini menggunakan bit gerudi berputar untuk mengeluarkan bahan, dan mereka penting dalam pengeluaran komponen yang memerlukan lubang yang tepat dan seragam. Industri seperti pembinaan, kerja logam, dan elektronik secara besar-besaran bergantung kepada penggerudian CNC untuk keperluan pembuatan mereka.

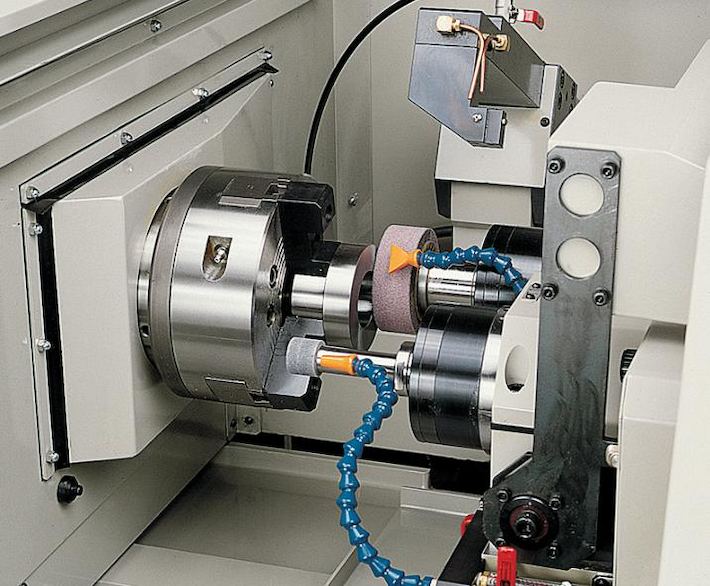

Apabila ketepatan melampau dan kemasan permukaan adalah penting, pengisaran CNC mula dimainkan. Kaedah ini menggunakan roda kasar untuk mengeluarkan bahan dan mencapai toleransi yang ketat. CNC grinding sangat diperlukan dalam pengeluaran alat, acuan, dan komponen ketepatan tinggi yang digunakan dalam peranti perubatan dan kejuruteraan aeroangkasa.

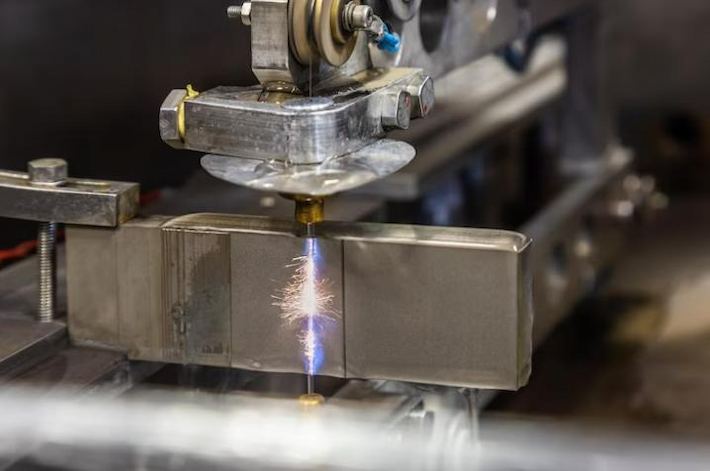

EDM adalah kaedah pemesinan CNC bukan tradisional yang menggunakan pelepasan elektrik untuk membentuk bahan. Dengan percikan api elektrik yang dikawal dengan teliti, EDM boleh mencipta bentuk rumit dan kompleks dengan ketepatan yang tinggi. Teknik ini amat berguna untuk logam keras yang mencabar untuk mesin dengan kaedah tradisional. Sebagai contoh, kami menggunakan pemesinan pelepasan elektrik (EDM) untuk menyesuaikan templat untuk acuan

Pemotongan laser CNC melibatkan penggunaan pancaran laser untuk memotong bahan, mewujudkan tepi yang tepat dan bersih. Kaedah ini digunakan secara meluas dalam pembuatan komponen logam lembaran untuk industri dari automotif hingga elektronik pengguna. Tahap ketepatan dan kelajuan yang tinggi menjadikan laser CNC memotong proses yang tidak ternilai dalam pembuatan moden.

Dalam landskap pembuatan yang sentiasa berkembang, dua teknologi canggih telah muncul sebagai peneraju: pemesinan CNC dan percetakan 3D. Setiap kaedah membawa set kekuatan dan aplikasi sendiri ke meja. Mari kita menyelidiki selok-belok pemesinan CNC dan percetakan 3D, membandingkan ciri, kelebihan, dan batasan mereka.

Pemesinan CNC (kawalan berangka komputer) adalah proses pembuatan subtractive. Ia melibatkan mengeluarkan bahan dari bahan kerja untuk mencapai bentuk yang dikehendaki. Proses ini menggunakan reka bentuk berbantukan komputer (CAD) dan perisian pembuatan berbantukan komputer (CAM) untuk tepat mengawal pergerakan alat memotong.

Pemesinan CNC terkenal dengan ketepatan dan ketepatan yang tinggi. Ia boleh mencapai toleransi yang ketat dan menghasilkan butiran rumit, menjadikannya sesuai untuk aplikasi di mana ketepatan adalah penting, seperti industri aeroangkasa dan perubatan. Pemesinan CNC adalah serba boleh apabila ia datang kepada keserasian bahan. Ia boleh mengendalikan pelbagai bahan, termasuk logam, plastik, dan komposit. Ini menjadikannya pilihan pilihan untuk industri yang menuntut ketahanan dan kekuatan dalam komponen mereka. Pemesinan CNC sangat sesuai untuk kedua-dua prototaip dan pengeluaran berskala besar. Walaupun masa persediaan untuk pemesinan CNC boleh lebih lama daripada percetakan 3D, ia cemerlang dalam menghasilkan bahagian yang berkualiti tinggi dan berfungsi. Pemesinan CNC menyediakan kemasan permukaan unggul berbanding dengan banyak teknologi percetakan 3D. Ini menjadikannya pilihan yang ideal untuk komponen yang memerlukan permukaan yang digilap atau licin.

Percetakan 3D, atau pembuatan aditif, membina objekLapisan oleh lapisan dari model digital. Ia melibatkan mendepositkan bahan dalam corak tertentu untuk mencipta sebuah objek tiga dimensi. Proses ini sangat serba boleh dan membolehkan geometri rumit.

Percetakan 3D menyokong pelbagai bahan, termasuk plastik, logam, seramik, dan juga bahan bio. Pilihan bahan terus berkembang, membuka kemungkinan baru untuk pelbagai industri. Kelebihan percetakan 3D dalam prototaip cepat dan sangat sesuai untuk geometri kompleks yang mungkin mencabar untuk pemesinan CNC. Walau bagaimanapun, ia mungkin tidak sepadan dengan kelajuan pemesinan CNC untuk pengeluaran berskala besar. Dari segi keberkesanan kos, terutamanya untuk pengeluaran dan prototaip volum rendah, percetakan 3D boleh menawarkan kelebihan kerana pembaziran bahan yang dikurangkan dan penyediaan yang lebih mudah. Percetakan 3D disambut untuk keupayaan penyesuaian. Ia membolehkan penciptaan reka bentuk yang unik dan peribadi tanpa memerlukan alat tambahan, menjadikannya sesuai untuk pengeluaran satu atau kecil.

Secara keseluruhannya, pilihan antara pemesinan CNC dan percetakan 3D bergantung kepada faktor-faktor seperti bahan, keperluan ketepatan, skala pengeluaran, dan kerumitan projek. Untuk larian pengeluaran yang lebih besar, pemesinan CNC cemerlang dalam ketepatan dan fleksibiliti bahan, manakala percetakan 3D bersinar dalam prototaip cepat dan aplikasi reka bentuk yang kompleks.

Kasi.

Pemesinan CNC (kawalan berangka komputer) memainkan peranan penting dalam pembuatan komponen ketepatan berkualiti tinggi. Berikut adalah langkah-langkah proses umum dan butiran untuk pembuatan bebibir CNC-machined:

Langkah-langkah proses untuk bebibir CNC-Machined:

1. Reka bentuk dan pemodelan:

Sebelum pembuatan komponen CNC, reka bentuk CAD (reka bentuk berbantukan komputer) adalah penting. Jurutera reka bentuk menggunakan perisian CAD untuk mencipta model 3D flange, menentukan bentuk geometri, dimensi, dan laluan pemesinan.

2. Penyediaan bahan:

Pilih bahan mentah yang sesuai, biasanya logam (seperti keluli tahan karat, aluminium, dan lain-lain). Pemilihan bahan bergantung kepada tujuan bebibir, persekitaran kerja, dan keperluan prestasi.

3. Proses pemesinan:

A. Roughing:

Gunakan alat pemotong pada mesin CNC untuk melakukan roughing, kira-kira membentuk bentuk keseluruhan bahan kerja.

Matlamat roughing adalah dengan cepat mengeluarkan bahan yang berlebihan, meninggalkan satu bentuk akhir anggaran.

B. Separuh penamat:

Gunakan alat yang berbeza untuk menyelesaikan separuh bahan kerja, terus menghampiri bentuk akhir.

Mengurangkan kelajuan pemotongan untuk meningkatkan kelancaran permukaan.

C. Penamat:

Gunakan alat kecil untuk pemotongan ketepatan akhir, mencapai dimensi akhir dan kelancaran permukaan.

Penamat sering melibatkan penggunaan alat yang lebih kecil untuk meningkatkan ketepatan pemesinan.

D. Lubang pemesinan dan memotong benang:

Gunakan alat khusus untuk pemesinan lubang dan pemotongan benang untuk memastikan flange memenuhi spesifikasi reka bentuk.

4. Pemeriksaan dan kawalan kualiti:

Selepas setiap langkah pemesinan, menjalankan pemeriksaan untuk memastikan dimensi, bentuk, dan kualiti permukaan bahan kerja memenuhi keperluan spesifikasi. Kaedah pemeriksaan biasa termasuk mengukur koordinat, ujian kekasaran permukaan, dan ujian ultrasonik.

5. Rawatan permukaan:

Bergantung kepada keperluan, melakukan rawatan permukaan seperti penggilap, sandblasting, atau salutan untuk meningkatkan penampilan dan rintangan kakisan.

6. Pembungkusan dan penghantaran:

Selepas melengkapkan pemesinan dan pemeriksaan, pakej bebibir mengikut keperluan pelanggan dan meneruskan penghantaran.

Pemesinan CNC (kawalan berangka komputer) adalah proses pembuatan di mana perisian komputer pra-diprogramkan mengawal pergerakan jentera dan alat. Proses ini membolehkan penciptaan bahagian yang sangat tepat dan kompleks dari pelbagai bahan, termasuk logam dan plastik. Pemesinan CNC digunakan secara meluas dalam industri seperti automotif, elektronik, dan aeroangkasa.

CNC turning sangat sesuai untuk menghasilkan bahagian silinder atau bulat, seperti aci, bushings, skru, dan pin. Ia biasanya digunakan untuk komponen yang memerlukan ketepatan tinggi dan permukaan licin. Industri seperti automotif, perubatan dan elektronik mendapat manfaat daripadaChina aluminium bertukar bahagian.

Cari pembekal dengan pengalaman yang luas, peralatan moden, dan komitmen yang kuat terhadap kawalan kualiti. Pensijilan seperti ISO 9001 dan IATF 16949 menunjukkan pematuhan dengan piawaian industri. Juga, pertimbangkan faktor-faktor seperti kapasiti pengeluaran, masa memimpin, dan ulasan pelanggan.

Di HHC, kami menawarkan bahagian ketepatan dengan toleransi ketat ± 0.01mm, memastikan ketepatan yang tinggi untuk komponen yang paling kompleks. Peralatan canggih kami membolehkan kami mengekalkan konsistensi dan memenuhi keperluan khusus setiap projek.

Masa utama berbeza-beza berdasarkan kerumitan dan kuantiti bahagian, tetapi kami biasanya menyampaikan bahagian pemesinan CNC dalam masa 1 hingga 4 minggu. Kami juga menawarkan perkhidmatan dipercepatkan untuk projek segera untuk membantu pelanggan kami memenuhi tarikh akhir yang ketat.